3D Printing: A complete guide

Photo: S zillayali

What is 3D printing?

3D printing is another

term for additive manufacturing – the process of building an object

layer by layer, controlled by a computer. You may know it as the process

of building small objects out of plastic from 3D computer models.

SEE ALSO: The Best Crowdfunding Projects This Month

What type of 3D printing are we talking about?

There

are many different 3D printing processes in existence, including ones

that allow you to print in metal and ceramic materials or which used

powdered materials. However these are prohibitively expensive and won’t

be available to most people. So for this guide we’ll be covering just

FDM (Fused Deposition Modelling) and SLA (Stereolithography) which are

available in the consumer market.

Commercial 3D printing

Though

3D printing has been around in one form or another since the ‘80s, the

possibilities of the latest generation of 3D printers are being realised

across the commercial world, and it’s not just for printing out

proof-of-concept models and hobbyists’ knick-knacks.

For

example, Airbus has enlisted Stratasys to 3D print 1000 parts for its

A350 XWB jet, while GE jet engines are being fitted with a sensor mount

3D printed in cobalt chrome alloy. At the consumer products end of the spectrum, AudioQuest’s NightHawk headphones (above) feature 3D-printed parts in their earcups (below) that couldn’t be produced using traditional manufacturing methods.

Buying your own 3D printer

If

you’re looking to buy your own 3D printer, your choice will depend both

on budget and the sort of objects you intend to print. The most

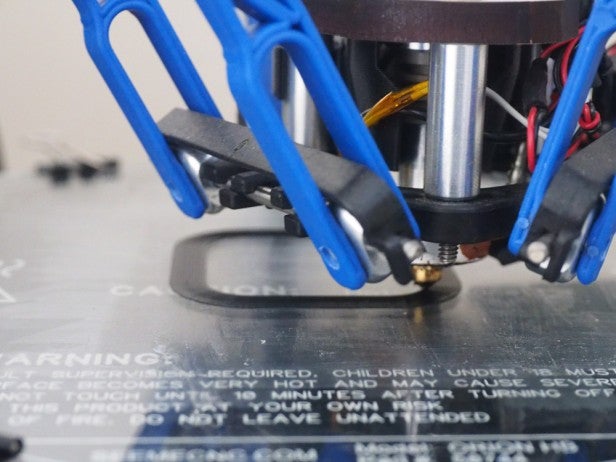

wallet-friendly 3D printers are all FDM models which pull in plastic

filament, heat it up and squirt it (extrude) out of a nozzle.

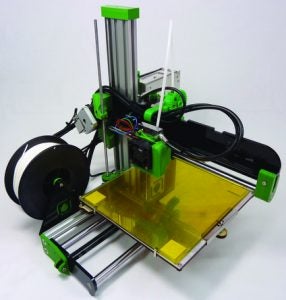

If you’re handy and/or very cash-strapped, you could build your own. The RepRap project is a good place to start. It began with the aim of creating a low cost 3D printer that could ‘self-replicate’ by printing a kit version of itself.

You can buy a kit such as the RepRap Pro Ormerod 2 above, or collect the individual parts yourself…

There are, of course, plenty of fully-assembled FDM 3D printers available too, such as the SeeMeCNC Orion with its unusual 3-arm delta design.

Related: SeeMeCNC Orion full review

If you want to go really cheap and crafty, you could try the sub-£100 3Doodler which is a bit like a 3D printer but without the movement.

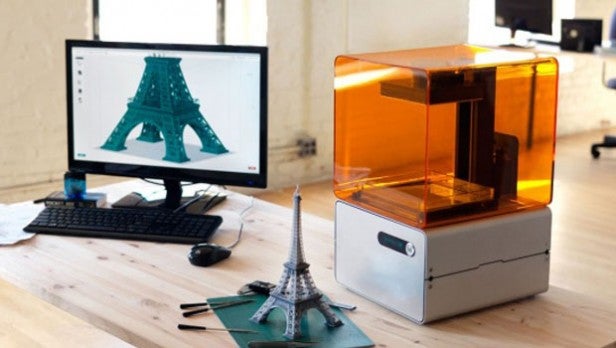

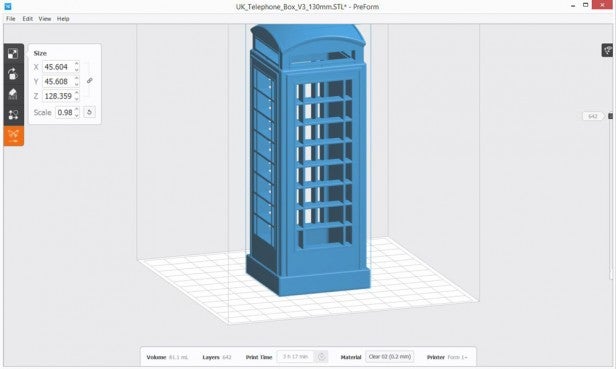

If

you’ve got a bit more cash to spend, the Formlabs Form 1+ is a very polished

machine that produces stunning results. It’s an SLA (Stereolithography) printer that, instead of melting plastic, hardens UV-sensitive resin layer by layer. It’s capable of extremely fine detail and is more reliable than most FMD printers but also a lot more expensive at €3399 plus high running costs, so is more business-focused.

Things to consider

As with any tech, it’s important to know what’s important to you before buying.

How

big are the objects you want to make? Build volume denotes the maximum

dimensions of the objects you can build with a printer. Bigger usually

means more expensive.

What materials do you want

to be able to print in? Some materials are more costly or messier than

others. Biodegradable PLA plastic is cheap, it’s made from cornstarch

and doesn’t smell too bad when you heat it up. Meanwhile ABS is tougher

and can produce finer models, but it’s more expensive, needs higher

temperatures and plenty of ventilation to get rid of its not-so-friendly

fumes. The resin used by SLA printers is even more expensive, but capable of more detailed results.

There are also a number of exciting new materials emerging that have glow-in-the-dark, rubbery, metallic and other properties for specialist models.

Do you need more than one extruder? Some FDM printers allow you to print

with multiple colours of material, or even different types of material

in the same print. To do this they use more than one extruder and

nozzle.

Do you want and auto-levelling build platform? As 3D printing becomes

more mainstream, machines are losing a bit of their make-in-a-shed

qualities. No longer do you necessarily have to spend ages levelling the

build platform every time you want to start a new print as many will

take care of this infuriating process for you. Progress!

What to build?

Once

you’ve got a 3D printer, you’ll need something to print. It’s unlikely

you’re already a master of 3D modelling, but that’s okay because there

are plenty of places you can find something lovely to print on your new

toy.

Most people will start a site such as Thingiverse (Makerbot’s 3D file community), YouMagine , Cubify or GrabCAD.

Popular DIYers and hackers site Instructables also has its own 3D printing section, and you might be surprised to learn that even NASA has its own catalogue of free-to-use 3D-printable models such as the Hubble telescope, above.

Design your own

Once

you’ve got the hang of bashing out a decent print, you’ll want to start

designing you own, or tweaking existing models to better fit your

needs. There are a number of great free 3D modelling programs you can

get stuck into.

By this time you’ve hopefully learned a bit about

what sort of models print well and which ones don’t, so you can

incorporate this into your own designs. For example maintaining a

minimum wall thickness, hollowing out solid objects where possible and

taking support material requirements into account.

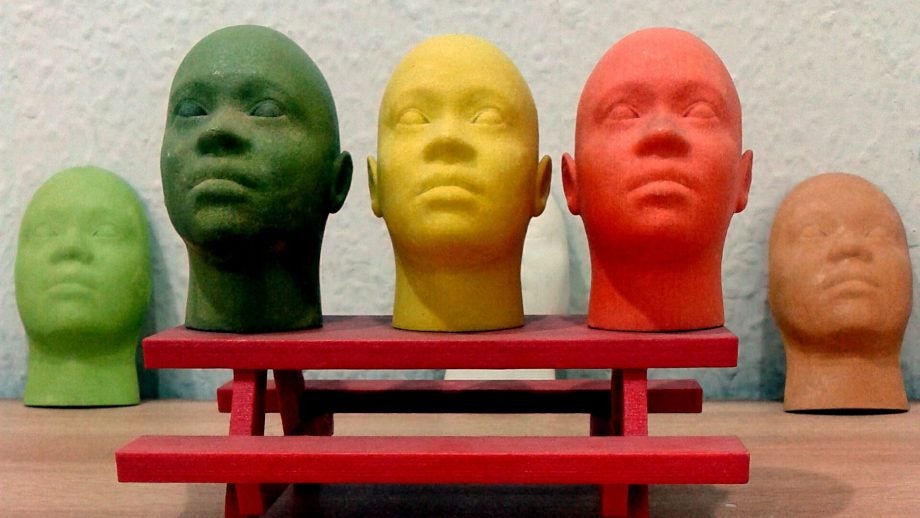

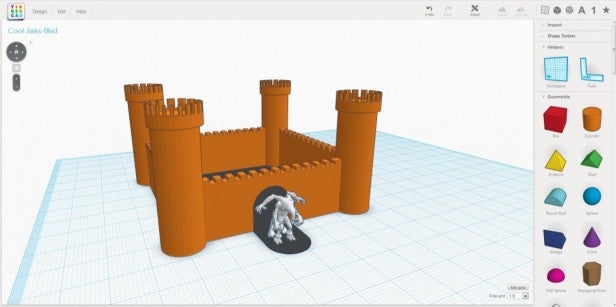

Autodesk’s

TinkerCAD is free and it’s a great place to start. Otherwise, if you

want to create your own mini-me you could try its 123D Catch app that turns a series of photos into a

3D-printable model.

Google Sketchup, Blender, Autodesk Inventor, Solidworks and Rhino are all options too, though the latter ones are more complicated.

SEE ALSO: 10 awesome things people are doing with 3D printers

Or get someone else to print it

Hopefully that’s all you need to sail off into the world of 3D printing with confidence, but if you don’t plan to buy your own printer or you have one but want to try printing in more exotic materials, companies such as Sculpteo

or Shapeways have industrial printers that will print your models

in a variety of different materials including ceramic, rubber and a

selection of metals including titanium and platinum.

Happy 3D printing.