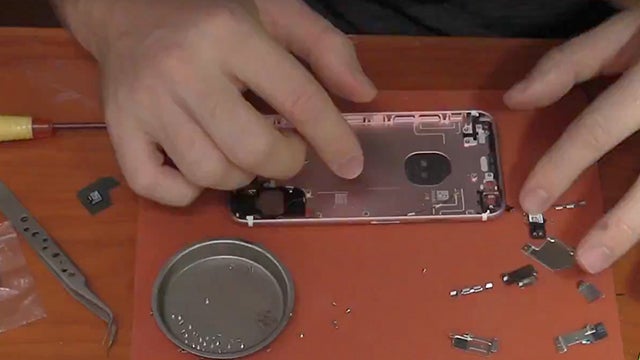

Watch this engineer make an entire iPhone using spare parts

If you’ve ever grown tired with how easy it is to simply hand over cash in return for an iPhone, you might now seriously consider building your own.

A new video from software engineer Scotty Allen shows how he was able to find enough spare parts to assemble a working iPhone, all by himself.

Allen, who used to work in Silicon Valley, travelled to Shenzhen, China to source all the components, before assembling a fully functional 16GB iPhone 6S.

Related: iPhone 8

Allen wrote about the whole process in a detailed post where he explains how when he was in a “dimly-lit BBQ joint” in China, someone asked whether he thought it was possible to build your own iPhone.

After nine months, the engineer set out to find out, visiting the markets of Shenzen to source all the various elements needed to build one of Apple’s handsets.

He explains how some parts were hard to find: “In some cases, even iPhone 6s parts were a bit hard to come by (mostly the logic board).

“I keep asking people about this, and people keep saying things like “there should be more after Spring Festival” (which has come and gone) or “there should be more in a month or two”

And if you’re wondering why the engineer didn’t build himself a nice shiny iPhone 7, he writes in his post: “iPhone 7 parts are pretty hard to come by in the markets.

“It’s not totally clear why this is, but I have some ideas. A lot of the parts come from recycled/broken phones, and so it would make sense that there just isn’t that much supply yet.”

Related: What will the next iPhone be called?

He also states that he already has an iPhone 6S, which meant he could use the phone for comparison when building his own version.

The final phone is made up of four basic parts: screen, shell, battery, and logic board – all of which, in the end, Allen says cost around $300 – far less than the $549 Apple wants for the phone.

However, it seems the engineer spent a good deal more on parts and tools that he ended up not using:

https://twitter.com/statuses/852213021896171520

The video explains his process in a detailed way, so if you want to know just how he put the thing together check out the footage above.

Let us know your thoughts on the video in the comments.