HP BladeSystem c-Class – Blade Server Review

HP BladeSystem c-Class – Blade Server

HP has rewritten the book when it comes to blade servers and Dave is very impressed.

Verdict

”’Blade Costs: BL480c – £1,603. BL460c – £1,209.”’

Low-profile rack servers have always been a top solution for enterprise level data centres looking to make the most out of their server room, as they offer a high processing density for a given amount of floor space. However, times move on and these very same companies have different sets of priorities now making blade servers a superior solution and here we take an in depth look at HP’s latest BladeSystem c-Class.

The problem with massively dense rack cabinets is they cost a lot to run and large businesses don’t like to see their IT budgets being eaten away by utility charges. Furthermore, not only do rack servers consume plenty of power but they generate a lot of heat and this has to be dealt with by expensive dedicated air-conditioning plants. Support costs come into the equation as well as large rack server installations require plenty of trained support staff to manage and maintain them. When they were first introduced over five years ago, blade servers focused primarily on sheer processing density but, as you’ll see clearly with the c-Class, there’s a big shift in priorities with reduced power consumption, lower heat output, greater fault tolerance and improved management now much higher up the agenda.

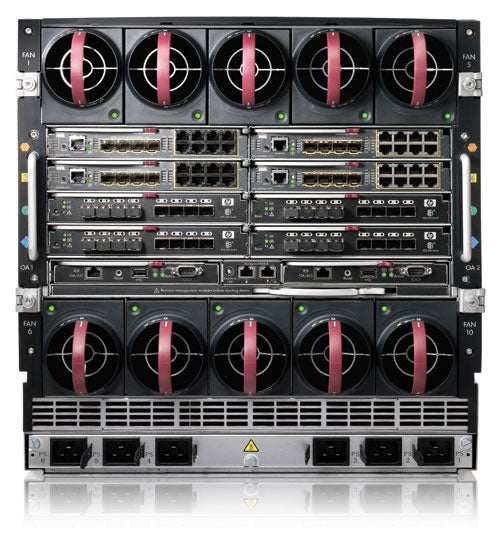

The first thing that strikes you about the c-Class is its superb build quality. HP was one of the first companies to introduce a blade server to market but with the c-Class it has thrown the rule book away and drawn on design concepts from every area of its server business including its Himalaya, SuperDome and ProLiant products. The c-Class is built around the 10U high 7000c enclosure which has room for up to sixteen half-height or eight full-height server blades and these all connect to a high-speed 5Tb/sec mid-plane. The only drawback with the new design is that the c-Class is incompatible with previous HP server blade offerings. When it released its BladeCentre H, IBM designed it to be fully backward compatible with previous chassis models allowing existing investment to be maximized as the old blades can be used in the new chassis and also replaced with newer models as they are released.

Nevertheless, HP does offer an extensive range of half-height and full-height server blades that support a wide range of processor options. Both Xeon 5100 and 5300 dual- and quad-processor blades are available along with AMD Series 2000 dual-socket and 8000 quad-socket models. HP even keeps the flag flying for Intel’s beleaguered Itanium 2 as the BL860c model supports the dual-core Montecito.

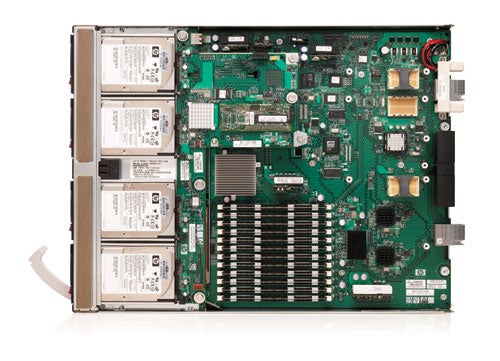

For server blade storage, HP prefers you to use SAS with the half-height DL460c, for example, supporting a pair of low-profile 2.5in hard disks in hot-swap carriers. All its blades offer RAID as standard and come with an embedded Smart Array controller and cache memory and the latter can be upgraded and protected with an optional battery backup pack. There’s even room to expand as the half-height blades have a pair of PCI-e slots that accept Gigabit Ethernet or fibre channel cards.

Each blade has a pair of embedded Gigabit Ethernet adapters and HP scores highly here as these incorporate not only a TOE (TCP offload engine) but even hardware iSCSI initiators allowing them to join an IP SAN. The latest blades also have integrated USB ports on their motherboards allowing internal USB security dongles to be installed or used to boot servers from flash memory.

Naturally, the full height blades have a lot more potential and all provide four hot-swap 2.5in. hard disks bays with support for RAID-5 as well as mirrors and stripes. It’s not so valuable with only four drives to play with but the Smart Array controllers also offer RAID-6 which requires a minimum of four drives to function but can survive the loss of two. The network connections are doubled up as well as these blades provide four Gigabit Ethernet ports. Network port count can also be increased on the half-height blades with the new quad Gigabit mezzanine card which is aimed primarily at server virtualisation environments. As with its ProLiant servers, all server blades incorporate an embedded iLO2 management controller allowing them to be remotely monitored and managed from HP’s Insight Manager software.

The storage picture looks even brighter as HP recently introduced the SB40c blade which can provide direct attached storage to the servers. It has room for up to six hot-swap SAS or SATA drives and combines HP’s P400 Smart Array controller along with a 256MB cache and battery backup pack as standard. There are some limitations as a single storage blade integrates directly with the server blade to its left and the full-height blades require an additional PCI-e mezzanine card installed. Furthermore, although the midplane is used to link the storage blade with the server this employs a PCI-e interconnect so hot-plug is not currently supported.

When a server blade is inserted, the mid-plane routes its network connections through to different switch blades at the rear. The chassis provides eight slots and you have a wide range of modules to choose from which includes 16-port pass-through modules and Gigabit switches – it’s worth noting that Cisco was given the task of designing them for the c-Class chassis. Gigabit over fibre is supported by modules which have eight fixed copper ports along with four mini-GBICs that accept SX, LX and long-distance LH fibre optic SFPs. Fibre channel SANs also get a look in as HP offers 12- and 24-port Brocade FC SAN switches as well. The chassis also accommodates HP’s very latest VC (virtual connect) module which comes with a pair of 10GbE CX-4 copper ports. This comes into its own for server redundancy as a failed server in one chassis can be replaced by a hot-standby server in another linked chassis and its MAC addresses will be passed across to the standby server as well.

The majority of enterprises will have tough security measures and full change management procedures in place so support staff can’t just swap blades without authorisation. HP has this covered as it provides virtual pools of MAC addresses that can be assigned to new blades when they are first installed. The pool is created and registered securely for the customer by HP and the process aims to accelerate hardware upgrades and new server deployments. HP also has initial integration with FC SANs covered as it offers a virtual connect module with a pool of unique WWNs.

Power is very well handled as a module at the back has room for six inputs which are routed through to hot-plug power supplies. These are accessible from the front below the blade slots and fault tolerance is so good that the blades will continue to function with three failed supplies. HP’s design flair even extends to cooling as the chassis has room for up ten hot-swap fan modules. The server blades have no cooling fans themselves allowing the chassis to handle this function. To improve air flow and reduce noise levels HP turned to jet engine design so each module uses a metal bladed fan that is shaped more like a turbine. Slots without fans installed are closed off with louvres and the chassis has thermal sensors fitted allowing it control the speed of each module. The fans aren’t dedicated to any particular component so air flow from all installed modules is spread equally across the chassis allowing it to tolerate failures.

For local management and to facilitate initial deployment, the chassis offers an operator panel and LCD display. From here you can run fault analysis, assign IP addresses to the chassis and selected blades and monitor general system health. Remote support staff get a look in as well since the panel and display can be used for text based chats between staff on the scene and central support. Separate blades deliver full management facilities and these provide their own embedded iLO2 controller and a dedicated network port allowing access to be secured on a separate subnet. Management is also covered by fault tolerance as a pair of these blades can be fitted for redundancy.

The chassis provides comprehensive remote browser management as it features HP’s Onboard Administrator which opens with a complete rundown of the status of the entire system along with colour coded icons for errors and faults. The intuitive interface makes it simple to locate and access each function and photo-realistic pictures of the front and rear of the chassis provide a quick view of all installed components. As you’d expect, power management has a very high priority and you can view chassis power consumption, available power, current and maximum BTU/hr and temperatures. The power supplies are more efficient when running at 100 per cent load so HP’s dynamic power saving mode will run selected supplies at this rate by placing others in standby.

To complete the management picture, HP offers its Insight Control Data Center Edition which comprises a range of software modules you can pick and choose from as required. Modules are provided for swift OS deployment to multiple blades and HP can also supply pre-prepared images. There are options for BIOS and driver version control, patch management and performance monitoring and a new module is now available for managing server virtualisation. Central to all this is HP’s Systems Insight Manager which provides a wealth of information about the server and storage blades via the iLO2 management controller. Power gets a look in as well as Insight Manager now comes with enhanced features on power consumption as you can create reports on power usage by server blade or the complete chassis over selected time periods.

”’Verdict”’

For blade servers the main competition comes from IBM, Dell and Fujitsu Siemens and having seen them all we can safely say that HP’s BladeSystem c-Class is, literally, in a class of its own. Build quality, design and fault tolerance are superb, it offers an unbeatable choice of server and interconnect blades, hardware and power management and monitoring facilities are extensive and it looks very good value as well. Furthermore, as we write this review HP has advised us that it will be running a promotion during March where with selected specifications it will be offering the chassis free of charge.

The Onboard Administrator opens with a full status review of the chassis and all installed components.

—-

The Insight Display can link remotely with the chassis’ LCD control panel to show a graphical health summary.

—-

The local display panel can also be used to have text based conversations between central support and staff on the ground.

—-

HP’s power reporting is extensive and you can keep a close eye on consumption over a specific period of time.

—-

Insight Manager provides enhanced blade management and offers a comprehensive status display of each system in the chassis.

—-

Trusted Score

Score in detail

-

Value 8

-

Features 10